Last Updated on February 6, 2023 by Ryan

If you want to wire up VTEC in a non-VTEC car, you’ll need to first identify the wires that control the VTEC solenoid. Once you’ve found these wires, you’ll need to splice them into the corresponding wires on your car’s engine harness. Finally, you’ll need to connect a power source to the VTEC controller so that it can activate the solenoid.

- Remove the engine cover to access the engine bay

- Locate the vtec solenoid and unplug the electrical connector

- remove the two bolts holding the vtec solenoid in place with a socket wrench and pull it out of the engine bay

- Cut a 3-inch section of vacuum hose and insert it into the vtec line going to the intake manifold

- 5 Route the other end of this new vacuum hose to where you will be mounting your vtec controller unit

- Install your chosen vtec controller unit according to its instructions , then reconnect the electrical connector to the vtec solenoid

- Make sure all connections are tight

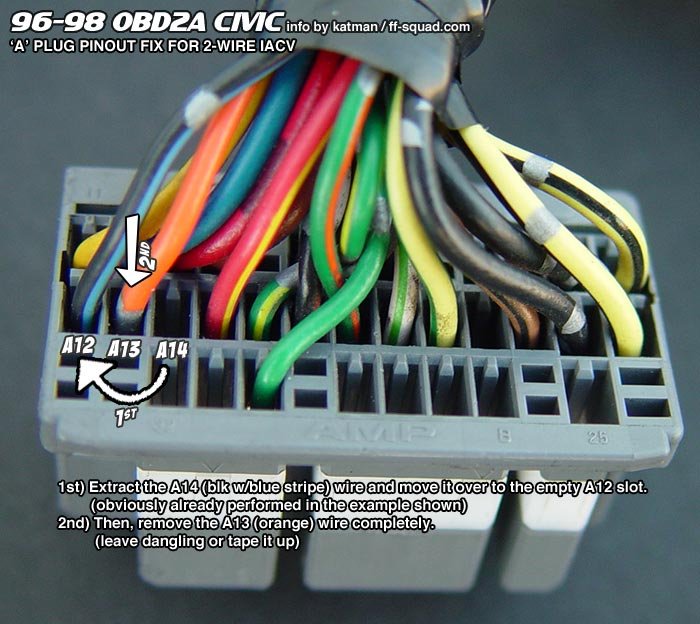

How To Wire VTEC In A Non VTEC OBD2 Honda Civic

Can You Install Vtec on a Non-Vtec Engine?

VTEC is a system that Honda uses to improve the performance of their engines. It stands for Variable Valve Timing and Lift Electronic Control. The VTEC system allows the engine to switch between two different camshaft profiles.

One profile is designed for low-end torque and the other is designed for high-rpm power. The VTEC system makes it possible for the engine to make more power without sacrificing fuel economy or emissions.

The answer to this question is no, you cannot install VTEC on a non-VTEC engine.

The VTEC system is specific to Honda engines and will not work on any other type of engine. Additionally, the VTEC system requires special hardware that is not found on non-VTEC engines. If you try to install VTEC on a non-VTEC engine, it will not work properly and could cause damage to the engine.

Can You Add Vtec to Any Engine?

VTEC, or Variable Valve Timing and Lift Electronic Control, is a system found on some Honda engines that allows for increased performance. VTEC can not be added to just any engine, as it requires specific hardware that most engines do not have. In addition, the engine management system must be programmed to work with VTEC in order for it to function properly.

For these reasons, VTEC can generally only be found on Honda engines.

Is Vtec Faster Than Non-Vtec?

In order to answer this question, we first need to understand what VTEC is and how it works. VTEC stands for Variable Valve Timing and Lift Electronic Control, and it is a system found in Honda engines that allows for variable valve timing and lift. This system can be used to improve engine performance, fuel efficiency, and emissions.

When activated, VTEC allows the engine to switch between two different camshaft profiles. The first profile is designed for low-rpm operation and offers reduced valve lift and duration. This results in increased torque at lower rpm levels.

The second profile is designed for high-rpm operation and offers increased valve lift and duration. This results in increased power at higher rpm levels. So, which one is faster?

That really depends on what you’re looking for. If you’re looking for more torque at lower rpm levels, then VTEC would be the way to go. However, if you’re looking for more power at higher rpm levels, then non-VTEC would be the better option.

How to Bypass Vtec Pressure Switch?

Assuming you are referring to a Honda VTEC pressure switch, bypassing it is not recommended as it can lead to engine damage. The pressure switch is there for a reason and bypassing it can put undue stress on the engine. That being said, if you are determined to bypass the pressure switch, here is how you can do it:

First, locate the pressure switch. It is usually located near the oil filter housing or on the firewall. Once you have found it, disconnect the two wires that lead to it.

Next, take a drill and make a hole in the center of the pressure switch. Be careful not to make the hole too big; just big enough so that a wire can fit through it.

Now take some wire and thread it through the hole you just made.

Make sure that both ends of the wire are long enough to reach their respective destinations (i.e., one end should reach the oil pressure sensor while the other end should reach ground). Finally, connect one end of the wire to ground and connect the other end of wire to wherethe oil pressure sensor usedto be connected..

Credit: honda-tech.com

How to Wire Vtec

If you own a Honda Civic with a B-series engine, then you might want to wire up your VTEC solenoid. This is not a difficult task, but it does require some basic understanding of automotive wiring. Here’s a step-by-step guide on how to do it:

1) Locate the VTEC solenoid on your engine. It should be located near the top of the engine, on the passenger side.

2) Unplug the electrical connector from the VTEC solenoid.

3) Using a pair of pliers, remove the two 10mm bolts that hold the VTEC solenoid in place.

4) Pull out the old VTEC solenoid and discard it.

5) Take your new VTEC solenoid and insert it into place, making sure that the electrical connector is facing downwards.

6) Replace the two 10mm bolts and tighten them down securely. Be careful not to over tighten them or strip the threads.7) Reconnectthe electrical connector tothe newVTECsolendiod .8 ) Start uptheengineto testthateverythingis working properly . If you experience any issues ,thenyou cancheck for leaks or other problems .

How to Wire Vtec to a Switch

If you own a Honda car with a VTEC engine, you may be wondering how to wire VTEC to a switch. While this may seem like a daunting task, it’s actually quite easy to do. Here’s a step-by-step guide on how to wire VTEC to a switch:

1) Start by disconnecting the negative battery terminal. This will ensure that there is no power flowing through the system while you’re working on it.

2) Next, locate the VTEC solenoid.

It’s usually located near the firewall on the driver’s side of the engine bay.

3) Once you’ve found the solenoid, remove the two bolts that hold it in place using a wrench or socket set. Be careful not to lose any of the small parts that may fall out when you remove the bolts.

4) With the bolts removed, carefully pull out the old solenoid and discard it.

5) Now take your new solenoid and install it in place of the old one, making sure to thread on all of the bolts tightly. Again, be careful not to lose any of the small parts during installation.

D16 Non Vtec to Vtec Conversion

If you own a Honda D16 engine and want to convert it to Vtec, there are a few things you need to know. The first is that the conversion will not be cheap. You will need to purchase a new cylinder head, intake manifold, exhaust manifold, and ECU.

The cost of these parts can range from $2000-$4000 depending on where you source them. You will also need to have your engine professionally rebuilt in order to accommodate the new parts. This can add another $1000-$2000 to the total cost of the conversion.

The second thing you need to know is that the Vtec conversion will not make your car significantly faster. The biggest difference you will see is in the higher rev range, where the Vtec kicks in and allows the engine to breathe better. However, this gain in power will come at the expense of fuel economy.

So if you are looking for a way to improve your car’s performance without breaking the bank, this may not be the best option for you.

Conclusion

If you want to wire up VTEC in a non-VTEC car, there are a few things you need to know. First, you need to find the 12V power supply wire and the ground wire. Next, you need to find the wires for the cylinder head temperature sensor and the oil pressure sensor.

Finally, you need to find the wires for the camshaft position sensor and the crankshaft position sensor. Once you have all of these wires, you can start wiring up VTEC in your non-VTEC car.